Deze website maakt gebruik van cookies om uw gebruikservaring te verbeteren. Door verder te surfen, stemt u in met onze Cookie en Privacy Policy. Accepteer

GZC 750

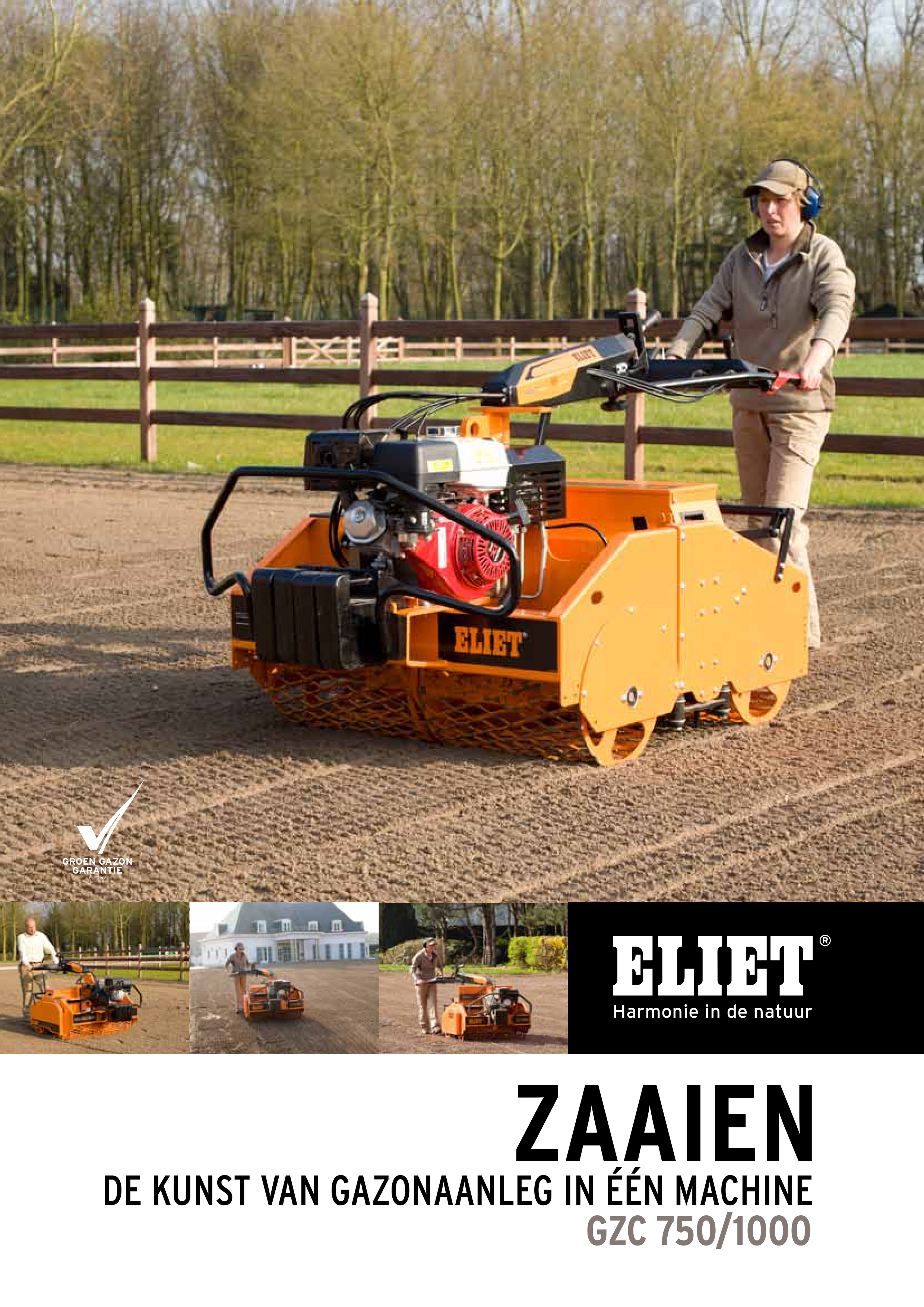

ALLE BEWERKINGEN VOOR GAZONAANLEG IN ÉÉN MACHINE

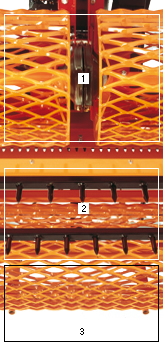

1. Verkruimelen

De eerste verkruimelrollen dragen het meeste gewicht van de machine. Bij het aanleggen van het terrein komen deze rollen het eerst in contact met de ruw voorbewerkte grond. Deze gemaasde rollen zullen de grond voor een deel vlak drukken en de grote aardekluiten zullen reeds verkruimeld worden.

2. Inzaaien

De schudeg van de ELIET Combi bestaat uit een dubbele tandenrij die lateraal heen en weer beweegt. Deze tandenrijen zijn achter de strooizone van de zaaibak geplaatst, zodat het zaaigoed onmiddellijk ingewerkt wordt bij het inzaaien. De schudeg kan in de diepte worden versteld met een zesstandenhendel, die zich binnen handbereik bevindt. Met deze diepteregeling verloopt het nivelleren volledig naar wens. De schudeg maakt de structuur van de toplaag los en verdeelt de aarde gelijkmatig over de werkbreedte. Oneffenheden in het oppervlak worden keurig weggewerkt.

3. Afwerken

Dankzij de schudeg wordt het gazon onmiddellijk onder een laagje aarde bedekt, veilig weg van de wind of gretige snavels. De achterste verkruimelrol drukt de grond net voldoende aan, zodat het ingezaaide graszaad goed omsloten zit. De grond blijft echter voldoende luchtig voor een snelle absorptie na regenval. In deze veilige habitat onder de toplaag is de vochtigheidsgraad ideaal voor het zaad, dat sneller zal ontkiemen.